Skip to main content

Past and Current Projects

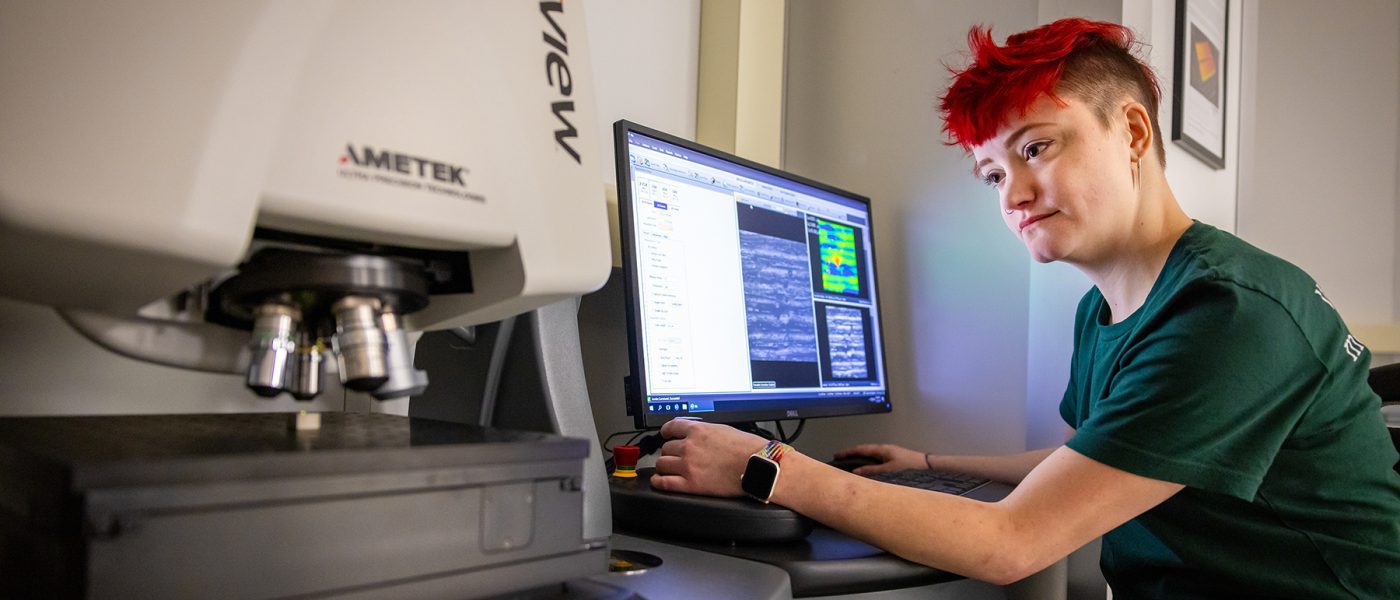

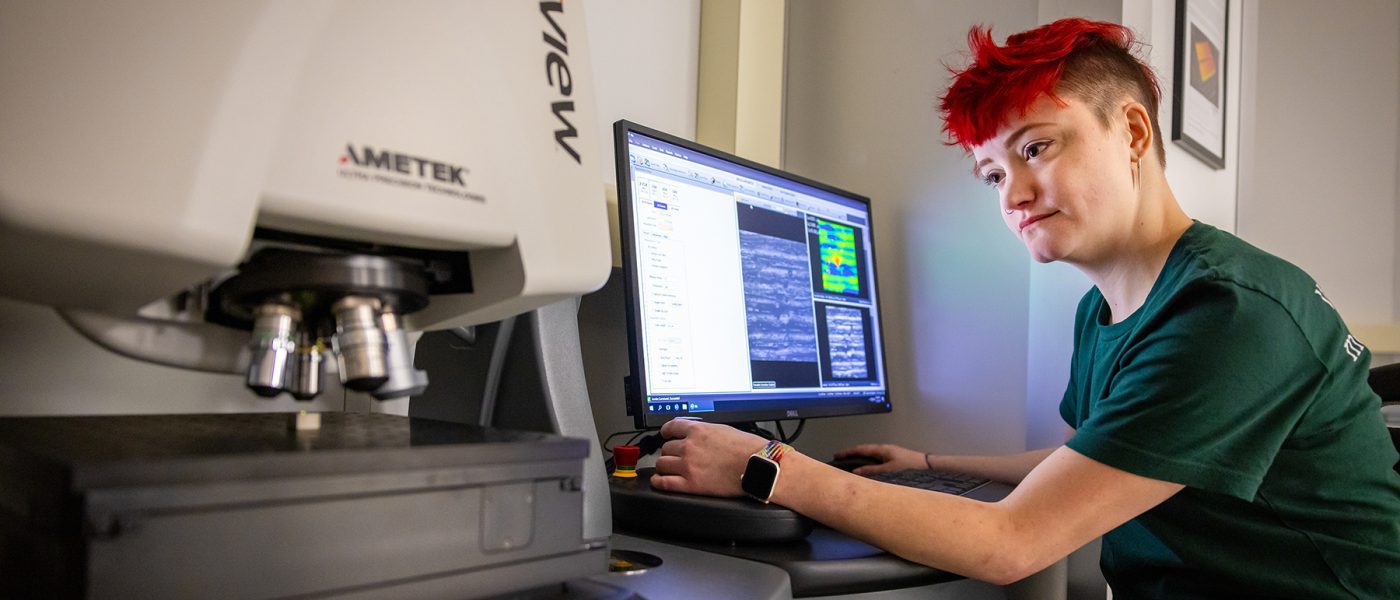

Taylor Barrett-Crvich uses a coherence scanning interferometer to measure the surface of a part (Zygo Nexview CSI)

Taylor Barrett-Crvich uses a coherence scanning interferometer to measure the surface of a part (Zygo Nexview CSI)

- 3D structure function of surfaces

- 3D tolerance control

- 5 axis coordinate measuring machine (MCM) uncertainty

- Adaptive sampling techniques

- Characterization of structured surfaces

- CMM contact scanning of edges and corners

- Combined moire-interference metrology • Environmentally tolerant SWLI characterization

- Error budget software for machine tools • Freeform metrology

- Laser tracker dynamic performance

- MicroCMM baseline metrology

- Non-axisymmetric artifacts

- Open metrology software

- Rough surface metrology

- Part manufacturing information

- Scanned profile uncertainties

- Spectral imaging metrology

- Tolerance specification consistency

- Vision CMM calibration techniques

- Wavelength shifting interferometry

- Compressed sampling microscope

- Computed tomography standards

- Dynamic range extension for optical imaging

- Fast tool servo for diamond turning non-axisymmetric components

- Giant magnetoresistive sensor design

- Grazing incidence metrology

- Instrumentation for crankshaft metrology

- MilliKelvin temperature control

- Nanoimprint lithography positioning stage

- Nanometric dilatometer

- Nanoscale hardness instrumentation

- Speckle scales for two dimensions

- Sub-atomic measuring machine

- Vectored touch sensor

- Wavelength stabilization of laser diodes

- Wettability characterization

- Whitelight fiber optic interferometry probe

- X-ray microscope development

- Ceramic machining

- Deformation machining

- Diamond films for manufacturing

- Error correction for freeform machining

- Machine tool geometric error correction

- Metals affordability initiative

- Molecular dynamics of machining

- Process damping in milling

- Subscale machining of large components

- Thermal modeling

- Tool tuning for machining centers

- Tool path modulation characterization

- Vibration assisted diamond turning

- Virtual manufacturing